Range of Applications

The MAT Mix – Slurry Mixers have been specifically developed for producing a homogeneous, dispersed mixture (= disperse system) from liquid and powdery raw materials.

The MAT Mix – Slurry Mixers have been specifically developed for producing a homogeneous, dispersed mixture (= disperse system) from liquid and powdery raw materials.

MAT Mix – Continuous Mixers reach a high mixing performance while designed very compact.

The Unique Mixing Principle

In the MAT Mix – Slurry Mixer, the mixing process takes place in two different process zones (premixing zone and dispersing zone).

The continuous mass transfer between the two zones ensures maximum possible homogeneity of the mixture.

The mixing tools rotating at high circumferential velocity in the dispersing zone also produce very strong shear and cavitation forces causing an optimum colloidal dispersion of the slurry.

Exceptional Advantages

- Absolutely minimal sedimentation of the mixture

- No post-swelling of the slurry

- Constant rheology of the product

- Lowest possible use of raw materials

- Low to high viscosity substances are processable

- High mixing capacity due to short mixing time

= Best product quality + utmost economic efficiency

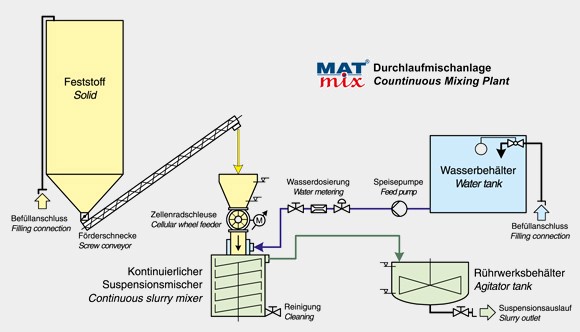

Process Flow Diagram

Product Range

| Type |

Mixing Capacity (m³/h) |

Power Input Total System (kW) |

Power Input Mixer (kW) |

|---|---|---|---|

| SKC-15-K | 4 – 15 | 30 | 22 |

| SKC-15-C | 4 – 15 | 30 | 22 |

| SKA-15-K | 4 – 15 | 30 | 22 |

| SKA-15-C | 4 – 15 | 30 | 22 |

| SKC-30-K | 8 – 30 | 30 | 22 |

| SKC-30-C | 8 – 30 | 30 | 22 |

| SKA-30-K | 8 – 30 | 30 | 22 |

| SKA-30-C | 8 – 30 | 30 | 22 |

| SKC-60-K | 15 – 60 | 30 | 22 |

| SKC-60-C | 15 – 60 | 30 | 22 |

| SKA-60-K | 15 – 60 | 30 | 22 |

| SKA-60-C | 15 – 60 | 30 | 22 |